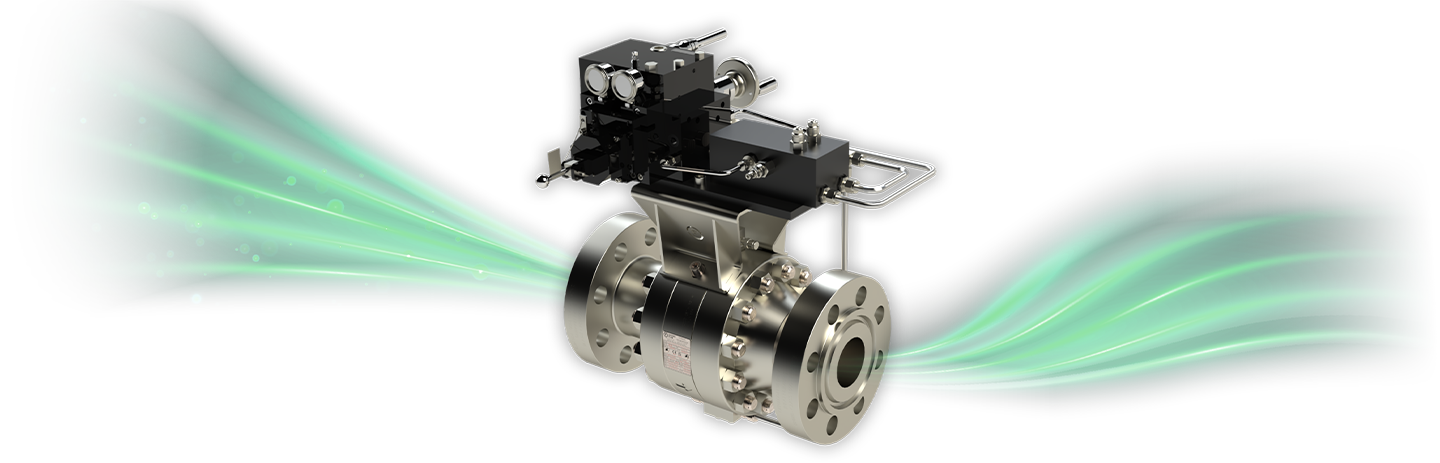

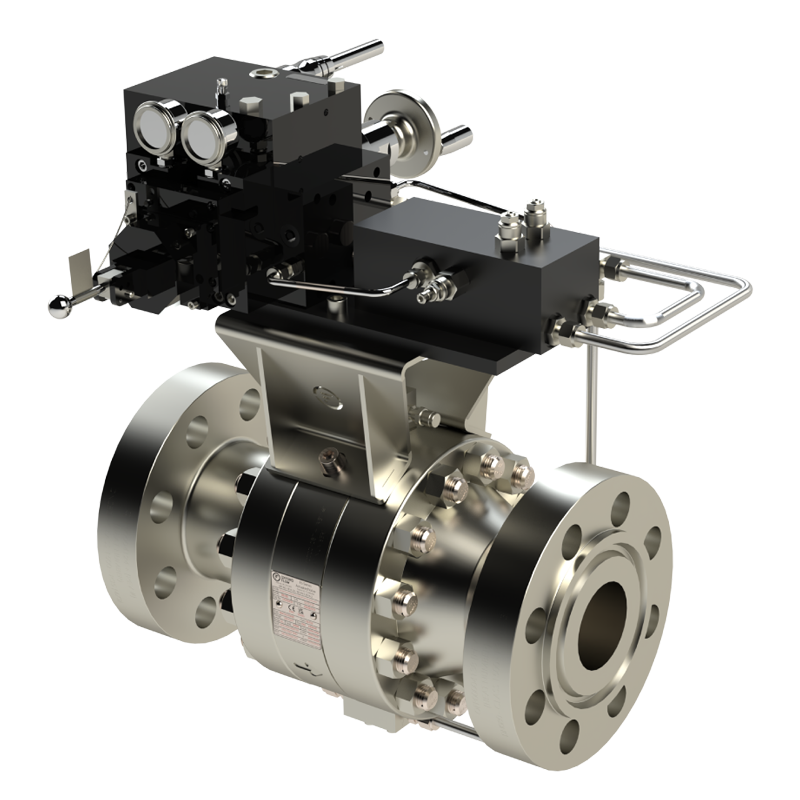

The ES stemless valves offer world class performance, reliability and emissions control for a wide range of severe service applications in oil and gas, petrochemical and process industries. The ES stemless valves can also be used for transitioning energy systems, including hydrogen and biomethane applications. The ES provides zero-leakage isolation in a variety of materials and configurations from 2″ to 24″ (DN50 to DN600) and in pressures classes to ASME 2500#.

Transformed valve performance

The zero fugitive emissions ES stemless axial flow valves have fundamentally transformed valve performance. Because the ES stemless valves do not have an external stem, there is no possibility of fugitive emissions through stem packing leaks. Further, because it does not have a mechanical drive train, it is not subject to stresses and side loading that cause poor performance and premature mechanical failure in other valve types.

Significantly reduced size and weight

With its pressure-balanced trim, the ES can be operated by a compact Electrohydraulic Powerpack, significantly reducing the size and weight of the valve package.

Reduced erosion and long-term zero leakage

The valve internals are also designed to provide very high flow rates while minimising turbulence. This reduces erosion on sealing surfaces and allows the ES to provide long-term zero leakage in a variety of severe applications.

Value Proposition

1

Designed to operate at restricted flow

and high differential pressure

Benefit

ES withstands high velocities with no cavitation while maintaining tight shutoff.

Value proposition

ES will reduce process downtime caused by valve failure.

2

Does not have an external stem

a primary source of emissions

Benefit

The ES does not require stem packing and maintenance to meet emissions requirements.

Value proposition

ES eliminates stem emissions, reducing OPEX related to valve packing.

3

Utilises an Electrohydraulic Powerpack

rather than a conventional actuator

Benefit

The Electrohydraulic Powerpack is compact, efficient in transmitting force, and only requires 24VDC power and a control signal.

Value proposition

The Electrohydraulic Powerpack reduces valve package size and weight by 50% and reduces installation cost by 30%.

Insights